Solutions

Automate Your Production

At Savya Automation, we understand that every industry and organization has unique requirements and challenges.

That's why we have developed a diverse portfolio of tailored solutions, including multi-component assembly solutions, end-of-arm tooling solutions, handling and transport solutions and many more. Our team of experts is ready to collaborate with you to optimize your production processes, enhance efficiency, and streamline operations. Discover how our innovative solutions can transform your business.

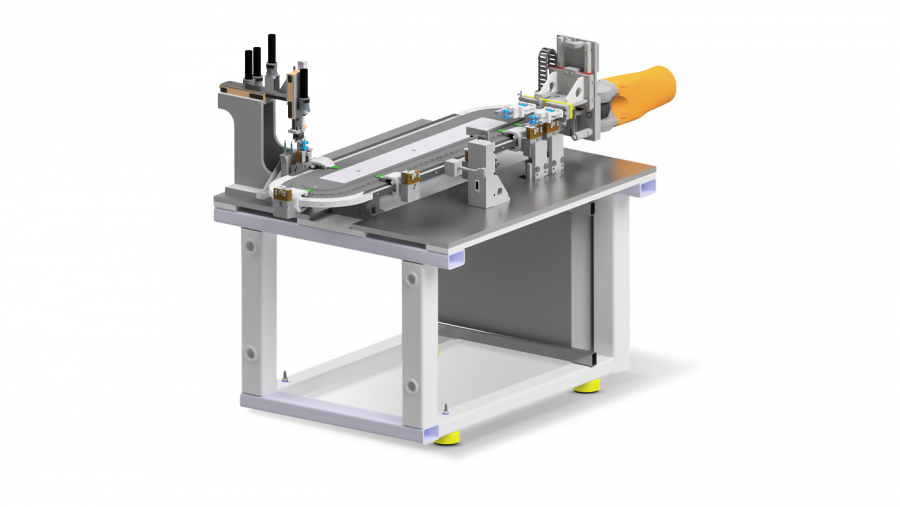

Multi-component

Assembly Solutions

Our multi-component assembly solutions are designed to streamline and optimize your assembly processes, enabling efficient production of complex products. With precision engineering and advanced technologies, we offer tailored solutions that ensure accurate component alignment, precise fastening, and seamless integration.

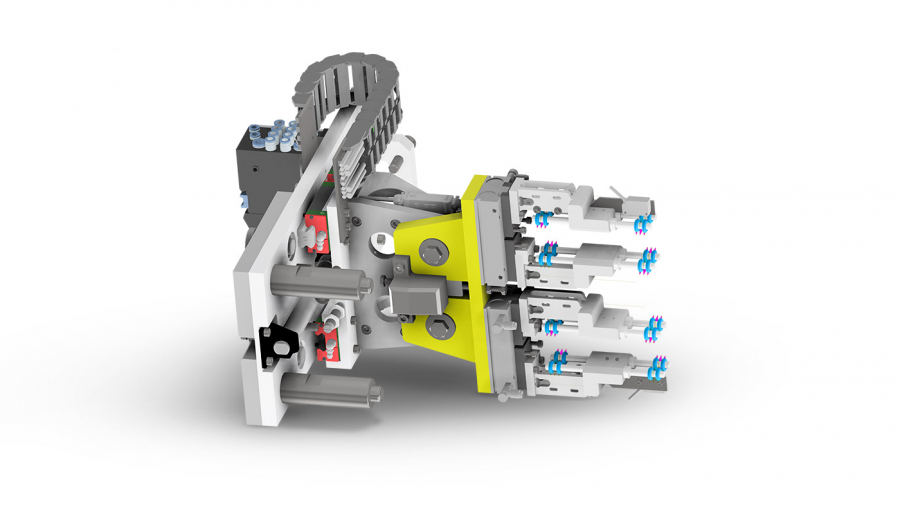

End of Arm

Tooling Solutions

Our end-of-arm tooling solutions offer a cutting-edge approach to robotic automation. With a range of customizable options, we provide efficient and precise end-of-arm tooling configurations tailored to your specific application needs.

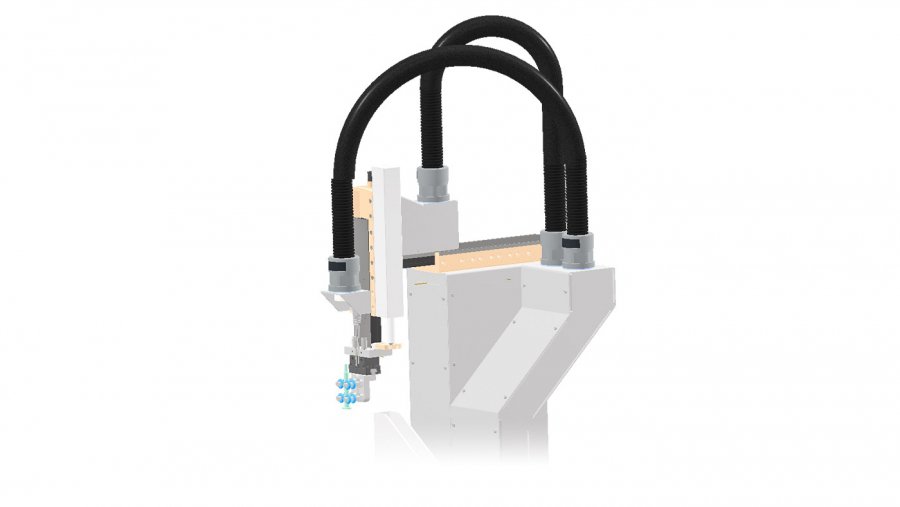

Part Handling and

Transport Solutions

Our part handling and transport solutions offer seamless automation for efficient material handling in your production line. Picture a small, versatile 2-axis robot expertly picking up parts from the transport system and precisely placing them into either the designated good parts box or the separate bad parts box. With precision and reliability, our solutions ensure streamlined and error-free part handling, maximizing productivity and minimizing waste.

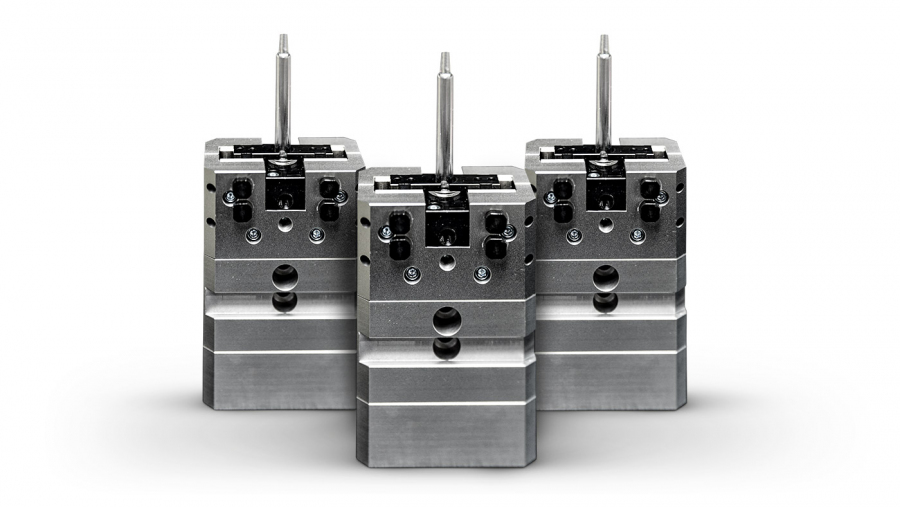

Product Carrier

Solutions

Introducing our State-of-the-Art product carrier solutions, designed to enhance your manufacturing workflow. A crucial element in the production line, our product carriers serve as robust platforms that securely hold and transport workpieces to their designated stations. With precise coordination and seamless integration, our solutions ensure smooth and efficient movement, enabling a streamlined production process.

Automation Solution

With Tray Changer

An automated handling system inserts precise components into the injection mold and removes the finished, overmolded parts. The components are fed in using a combination of robot and conveyor technology. After shaping, the parts are transferred to a transfer system and further processed in a process station, where cleaning, assembly and quality control take place, among other things. A robot then takes over the sorting and depositing into trays, which are efficiently handled by an automatic stacking and destacking system.

Standard Modular

Take Out Cell

A versatile solution designed to optimize the post-injection molding process. A robotic arm efficiently removes the product from the injection molding machine, seamlessly transferring it to the production cell. Within the cell, the product undergoes inspection and is precisely sorted into the appropriate categories of good and bad. With its modular design, our take-out cell offers flexibility and adaptability to suit your specific production requirements.